- Product Description

- Additional Information

Product Details

| Size | 50MM, 100MM, 150MM, 200MM |

|---|---|

| Usage/Application | Pipe Wrapping/Binding |

| Type | Singal/Double Sided |

Enquire Now

Product Description

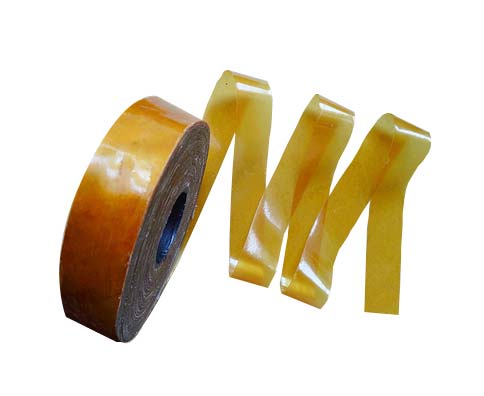

Anti Tape, Pipe Wrapping Tape, Wrapping Tape

Febolex is offering Wide Range of Anti Corrosive Tape high quality pipeline corrosion resistant tape confirming to IS 10221 specially produce for long term protection and range of high-quality pipeline corrosion resistant tape. Suitalble for the pipe protection of Gas Pipe Lines, Water Pipe Lines, Fire Hydrant Pipe Lines GI pipes, Buried Pipes & Fittings. This tape is also used for Insulation of underground Metals and cables against corrosion or Moisture ingress. Anti Corrosive Tape is basically made from water repellent flexible fabric which is treated with different chemicals & further coated with bitumen & self-adhesive insulating compounds on both sides. It is Self Bonding Anti Corrosive Tape.

Features of Anti Corrosive Tape

Product key Benefits of Anti Corrosive Tape

Uses of Anti Corrosive Tape

How to Use Anti Corrosive Tape

Prepare surfaces by removing all loose scale, rust or other foreign matter by wire brush. Surface must be clean, dry and free of grease. Now spirally wrap the tape with a minimum 1" overlap. For severely corrosive environments, a 55% overlap is recommended. While wrapping, press air pockets out and smooth all lap seams. For additional mechanical protection, an overwrap may be used to increase impact strength and electrical resistance